Mill-Turn

Where Milling Power Meets Turning Benefits

The advanced mill-turn solutions from the CHIRON Group combine high-performance milling, turning, and drilling in a unified, highly efficient machining process. These machines are equipped for full 5-axis simultaneous operations, offering comprehensive flexibility. Utilizing both the main and counter spindles, complete multi-sided machining is achievable, handling two operations at once. Expanded kinematics through swivel heads or integrated rotary spindles in a fourth axis enable this versatility. Material loading can be done continuously using a bar feeder, while integrated automation systems manage the loading of raw chuck parts and unloading of finished components to pre-set locations. The result are shorter cycle times, higher output, and top-tier accuracy from the very first workpiece, fulfilling your specific application needs through the CHIRON Group expert engineering.

What are the Benefits of Mill-Turn Machining?

Perfect for complex geometries, combines rotational and milled surfaces

Combines the benefits of two world's

Faster changeovers and shorter lead times

Superior workpiece consistency and accuracy

24/7 automation-ready for uninterrupted production

Reduces setup time and workpiece handling, improving efficiency and accuracy.

The mill-turn machines from the CHIRON Group combine high-precision milling and turning in one setup, using both vertical and horizontal process possibilities. Whether you're machining complex workpieces or maximizing efficiency, our machines deliver in power, speed, reliability and accuracy every time.

What Mill-Turn Technology Options do we offer?

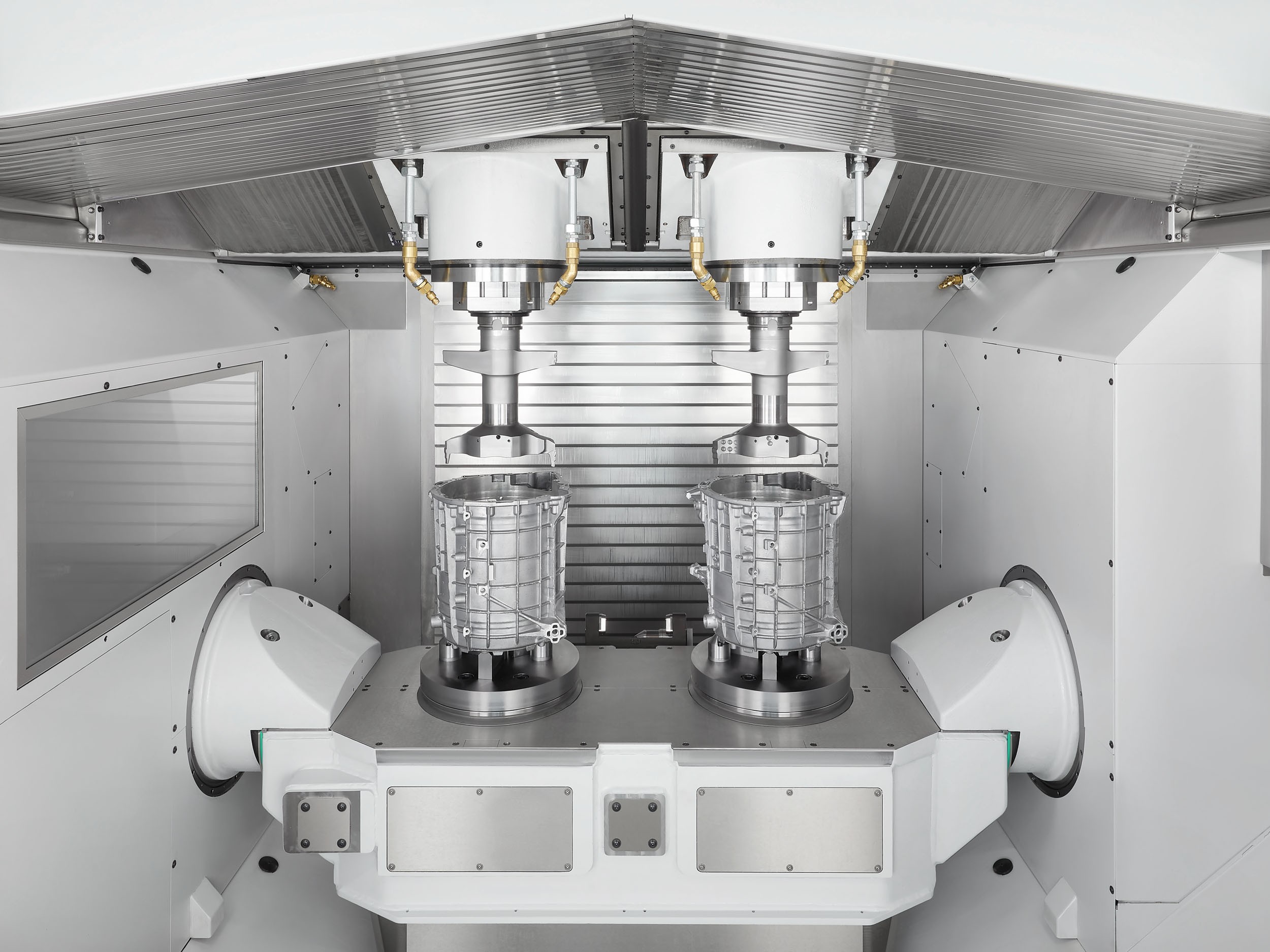

Vertical Mill Turn

Vertical mill-turn machining centers can perform both turning and milling operations without moving the workpiece to a different machine.

Vertical mill-turning machines can handle complex geometries and multi-surface machining with ease.

Vertical mill-turn allows for precise machining of large, heavy, or oddly shaped workpieces by combining turning and milling operations in a space-efficient setup.

Performing all operations in one clamping reduces the chance of alignment errors, leading to tighter tolerances and better workpiece consistency.

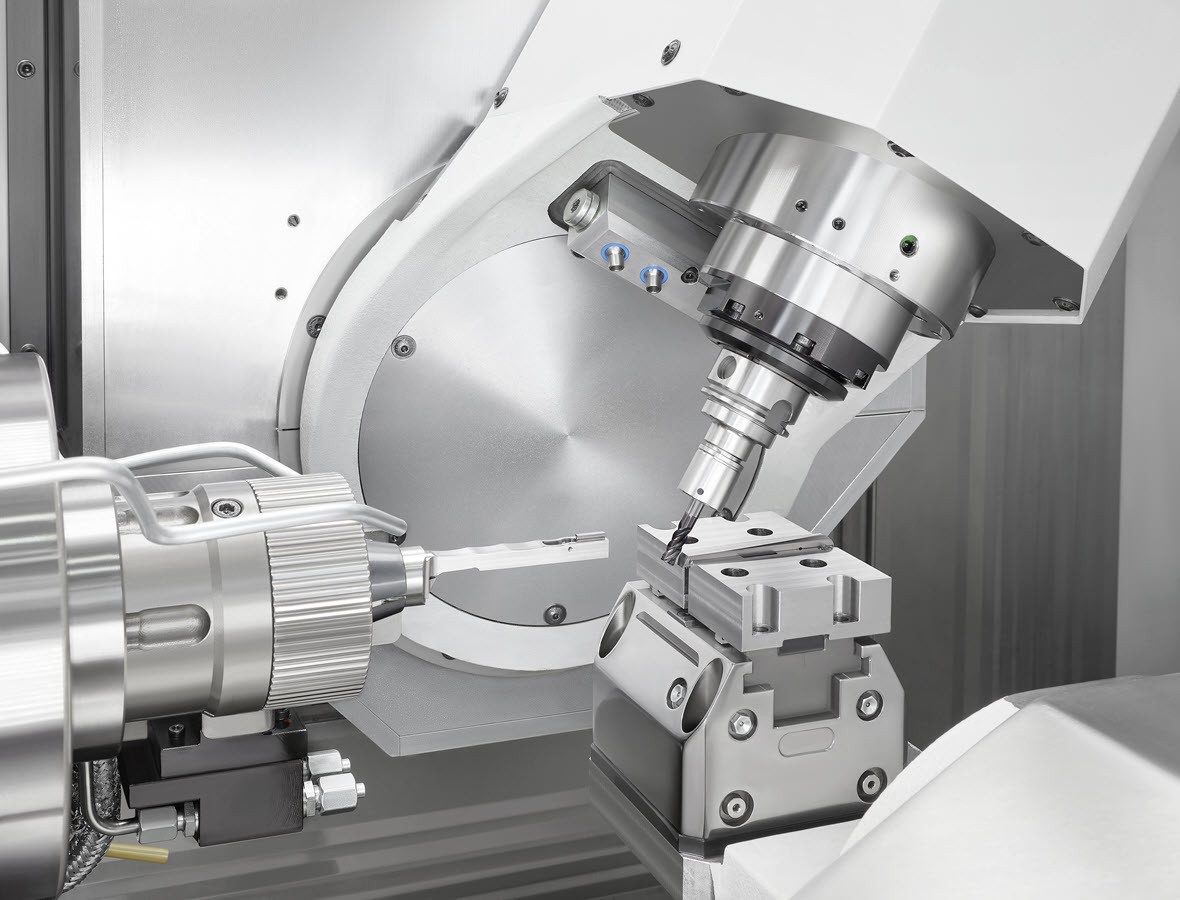

Vertical/Horizontal Mill Turn

Mill-turn machines often include a tailstock or steady rest, making them ideal for supporting long shafts, pipes, or cylindrical workpieces.

While the bar is in the loading process, the finished workpiece is unloaded on a pallet, minimizing idle time and boosting productivity.

Combining vertical and horizontal milling with turning operations, allowing workpieces to be machined on multiple sides without removing and re-clamping.

Reduces the need for multiple machines or setups, improving accuracy since there’s less risk of misalignment from repositioning the part.

Frequently Asked Question:

Why are Mill-Turn Machines important?

Mill-turn machines are important because they combine turning and milling as well as other operations like skiving, gear milling or drilling into a single machine, enabling the production of complex workpieces with greater efficiency and precision.

What Types of Workpieces Benefit from Mill-Turn Machining?

Components that require both turning and milling operations, such as parts with complex contours, machined features on cylindrical surfaces, or elements demanding high precision. As well as rotationally symmetric workpieces that include additional features like keyways, flats, or drilled holes.

How do our Machines deal with leftover pieces?

Once the machine knows that the workpiece is not able to be worked on, the integrated automation grabs the rest of the bar and puts it in a container or pallet.

Are Mill Turn Machines more expensive than normal milling machines?

Yes, mill-turn machines are generally more expensive than standard milling machines. This is due to their advanced capabilities and the integration of both milling and turning functions into a single machine.

»Flexible Mill-Turn Solutions: Precision Machining for Complex Geometries.«