Automation

Smart CNC Automation, Future-Ready Manufacturing

At CHIRON Group, automation is more than just an add-on, it's a strategic foundation of our approach to modern manufacturing. Our advanced CNC machining centers are designed with integrated automation capabilities that help manufacturers achieve greater productivity, efficiency, and flexibility. From robotic part handling and pallet changers to modular loading systems and intelligent control software, our automation solutions support everything from high volume production to small batch flexibility. We empower manufacturers to implement smart factory practices, reduce labor costs, and run reliable, around-the-clock operations. Whether you’re optimizing existing processes or building a fully automated production line, our automation expertise ensures your operations are ready for the future of industry.

What are the Benefits of Automation?

Run 24/7 with minimal operator intervention (use the second and third shift or produce into the night or weekends)

Lower labor costs and increase ROI

Increase OEE (overall equipment effectiveness)

Ensure consistent workpiece quality across every shift

Adapt quickly to changing production needs

Automating dangerous tasks increases safety and significantly reduces the risk to employees

Boost productivity, precision, and speed with the CHIRON Group intelligent automation, seamlessly integrated solutions built for demanding manufacturing. Scale efficiently, ensure consistent quality, and accelerate ROI for a future ready operation.

What Automation Technology Options do we offer?

Variocell UNO

- Micro-machining is entering a new era of productivity, sustainability, and automation — powered by the Micro5 machining center and Variocell UNO handling system. The compact 6-axis robot takes care of loading and unloading, ensuring greater autonomy and enabling significantly higher production volumes.

- With a Variocell UNO handling system, up to two Micro5 machines can be fully automated. Both the handling system and machining centers are integral components of the SmartFactory, alongside modules like the Pilot5 coordinate measuring system, laser markers, 3D printers, and cleaning units.

Variocell UNO

- Tailored to individual production needs, integrating various modules such as workpiece storage, double grippers, pallet stores, and peripheral units for cleaning, identification, or testing

- Its small footprint allows for fast cycle times and efficient handling of workpieces, helping to increase throughput and profitability without requiring extensive floor space.

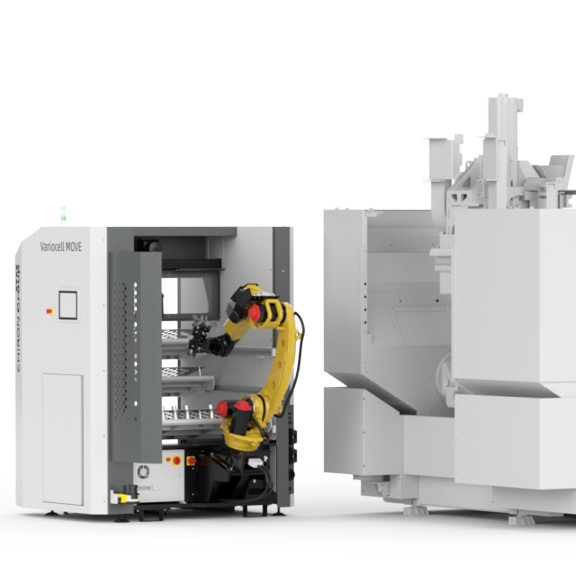

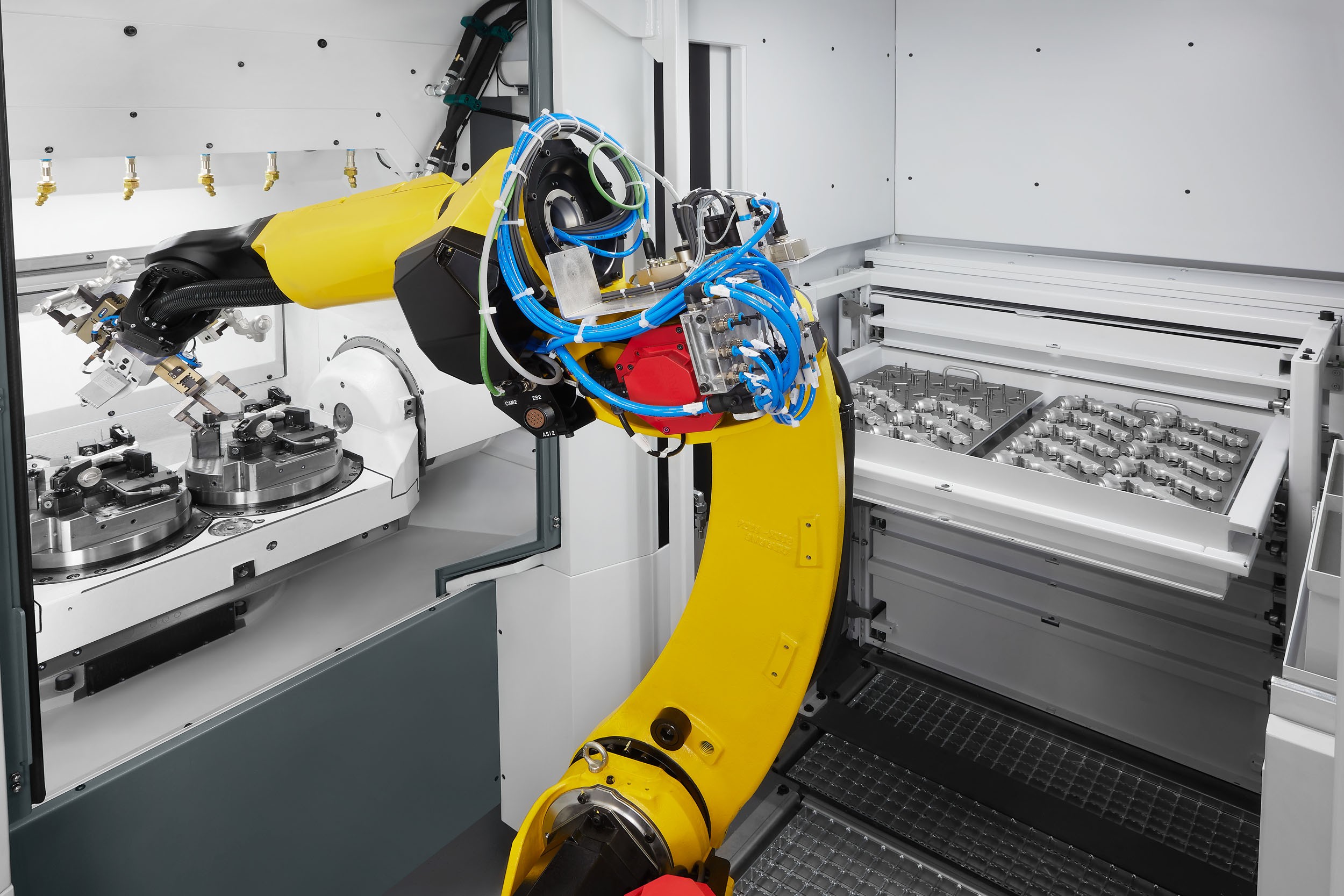

Variocell MOVE

- Maximize machine uptime, boost efficiency, lower unit costs, and ease the workload on operators, all with the Variocell MOVE. This compact robotic cell, featuring an inclined pallet system for smart workpiece handling. Whenever you need an automation system at a machine, you can "move" the Variocell MOVE wherever you need it to be. This Automation system can be paired with the 12, 15, 16, 18, MILL and baseline Series or machines of other manufacturers.

- When it comes to safety, laser scanners generate tiered safety zones around the Variocell MOVE. As an operator approaches, the system first slows down (Level 1) and then stops completely if necessary (Level 2).

Variocell PALLET

- Automation System that enables the clamping of various raw workpieces on a pallet with up to 10 pallets inside. The handling system feeds the pallet from the front of the machining center.

- Some of the benefits of the Variocell PALLET are, high productivity with batch size one autonomous production. High flexibility workpiece weight up to 300 kilograms (or 661 pounds), machine can move electrically by itself.

Variocell SYSTEM

- With the Variocell SYSTEM, you can automate the loading of one or more CHIRON Group machining centers while managing complex tasks with maximum autonomy and productivity. Designed around your specific requirements, this solution combines our expertise in automation with cutting-edge technology to deliver superior performance for your projects.

- Handling systems, gantry or articulated arm loaders, workpiece storage for blanks and finished workpieces, double grippers, pallet stores, as well as feeding and discharging equipment, complemented by peripheral units for cleaning, identification, testing, or measuring, are just some of the many modules our specialists use to configure your Variocell SYSTEM and create a highly automated manufacturing process.

Frequently Asked Questions:

Why are Automation systems Important?

Automation systems help lower the cost and increase in OEE, this means that there is less downtime through process stability and reliability. There is also no performance loss with no interruptions and increases product quality through repeatable workpiece loading.

Do you get any benefits from buying an automated system from the CHIRON Group?

Yes, there are benefits from buying automated systems from the CHIRON Group. One benefit is that customers are content when purchasing a automated system, they only have to contact one person, they receive one documentation, while also getting a service and warranty benefit.

How do CHIRON Group automation machines improve productivity and reduce cycle times?

Our automation machines technical availability is more than 95 percent and less than 5 percent, this leads to an increase in productivity, degree of utilization, and reduces downtime.

What makes automation systems unique at the CHIRON Group?

Automation solutions at the CHIRON Group stand out due to a combination of precision engineering, modular design, and seamless integration with high-performance CNC machines. The automation at the CHIRON Group is developed in-house and optimized for the company’s vertical and horizontal machining centers, ensuring maximum efficiency and reliability.

»Streamlining Efficiency: CHIRON Group Automation Solutions for Smarter Operations.«