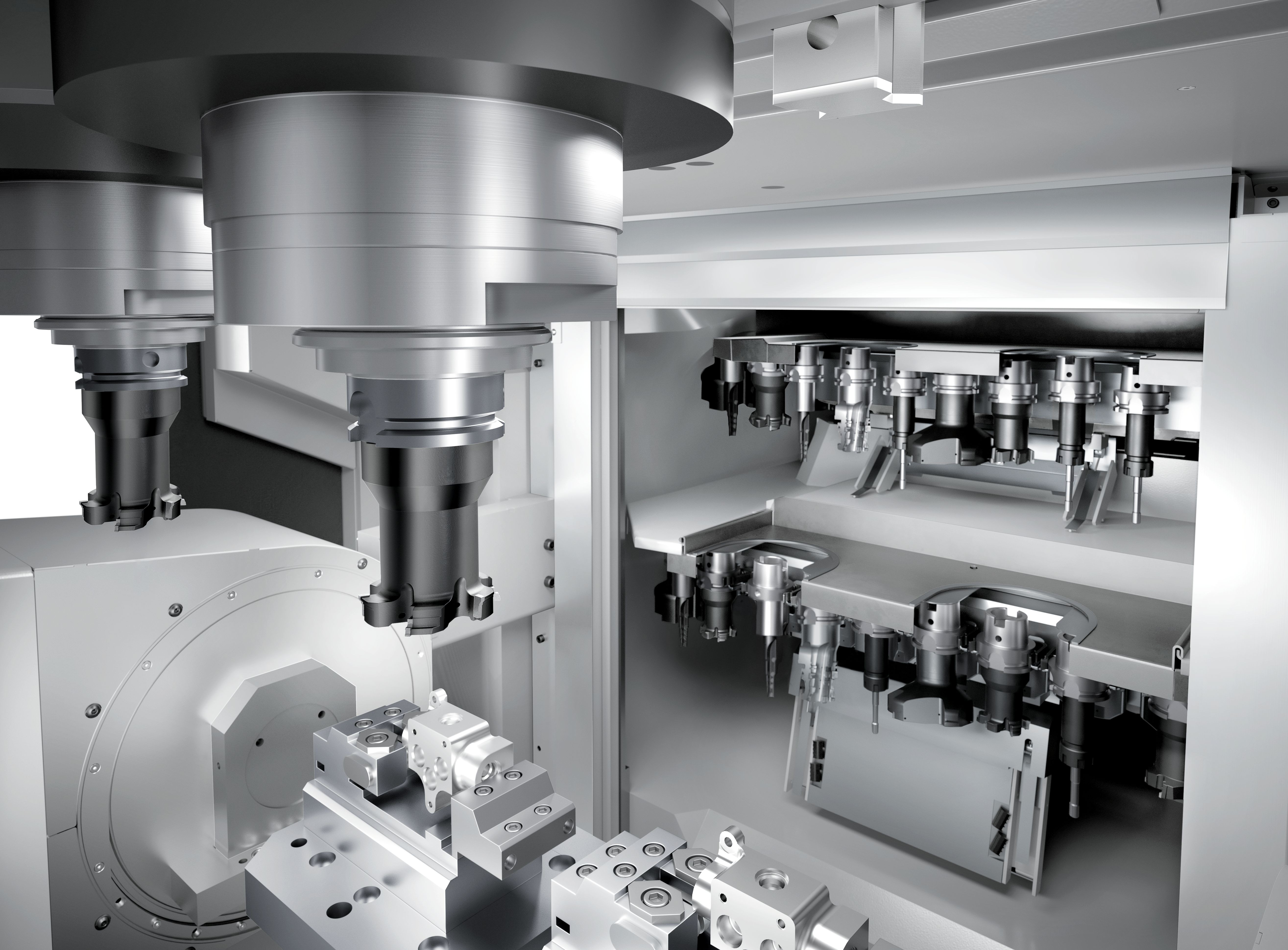

Double Spindle

Achieve Unmatched Cycle Times and Precision in High-Volume Production

Boost your productivity with powerful double spindle technology for high-volume, high-efficiency manufacturing. By incorporating two spindles within a single compact machine frame, CHIRON Group enables machining of two identical workpeices at the same time, effectively doubling productivity. Our double-spindle machines, feature independent Z-axes and advanced synchronization controls, allowing for both and parallel operations with exceptional precision. This setup reduces cycle times and ensures consistent workpiece quality across batches. By using a 2 spindle solution and setting up 4 workpieces in the fixture, the customers benefit can be even further improved. At the CHIRON Group, we focus on intelligent design and automation readiness, enabling seamless integration into production lines and maximizing throughout with accuracy.

What are the Benefits of Double Spindle?

Double your output with a lower investment than 2 machines

Higher output with same or slightly higher floor space requirement

Reduce automation quantity or requirements

Machine identical workpieces at the same time

Cut cycle times dramatically

Ensure consistency across large production batches

Capable of handling complex geometries and multi-process components

Experience the versatility of the twin-spindle machining centers from the CHIRON Group

This offer both independent spindle movements and fixed spindle configurations.

A wide range of spindle distances from 200 mm to 1,200 mm provides solutions for many workpiece sizes.

Solution for medium or large series production, with our twin-spindle solutions you are always one step ahead: with faster cycle times and maximum efficiency, double the performance – all in one machine.

What Double Spindle Technology Options do we offer?

Fixed Spindle

A fixed double spindle allows simultaneous machining on two spindles to boost efficiency and reduce cycle time.

The fixed spindle provides a stable and repeatable reference point for the transfer process.

The two spindles distances will always be the same everywhere the spindles travel.

Being fixed means it has a rigid and stable structure, which is critical for maintaining tight tolerances, surface finish, and concentricity.

Independent Spindle

Independent Spindles means that each spindle can operate autonomously, performing different machining operations simultaneously or at different times.

Each spindle can rotate at different speeds, operate simultaneously, and sometimes move along Z-axis.

Even though both spindles can move, one is often fixed or stationary during critical operations to maintain precision and coordination.

An independent spindle delivers maximum flexibility and productivity by allowing separate operations on multiple workpieces

CNC Machine with Adjustable Dual Spindle Positioning

The adjustable spindle positioning system can compensate for even microscopic misalignments, as small as 0.001 mm!

This ensures perfect synchronization during workpiece transfer, improving accuracy and reducing scrap rates.

This Technology helps to compensate tool clamping alignment errors or clamping errors derived from the fixture.

Frequently Asked Questions:

How does Double Spindle Machining improve Throughput?

Double spindle machining improves throughput by enabling simultaneous or independent operations on two workpieces or different operations on a single workpiece, effectively reducing cycle times and boosting productivity.

Are Double Spindle Machines good for Precision workpieces?

Yes, if tolerances are too tight to achieve them in a double spindle process the independent spindle design can be used for this operation and manufacture the critical tolerance by using one spindle only.

What are the Cycle Time benefits?

You can cut your cycle time by adding a second spindle, so you can work on one or two workpieces at a time.

What should be considered when purchasing a Double Spindle Machine?

When purchasing a double spindle machine, some things to consider are production needs, the machine's technical specifications, and its reliability. Specifically, assess the complexity and sizes of workpieces you'll be machining, the required precision, and the types of materials you'll be working with.

How do I choose between Single Spindle and Double Spindle?

When choosing between single and double spindle, it mostly depends on production volume. Single spindle machines are great for lower volume tasks, while double spindle machines excel at high volume machining while also lowering cycle times.

»Double Spindle Technology: Twice the Productivity, Half the Cycle Time.«