SmartServices: Digital Services – real added value

Wherever your machines are located in the world, SmartServices are always on hand to help you convert the potential of your manufacturing processes into increased profitability. The digital services of the CHIRON Group Service are based on the established software solutions from the SmartLine portfolio.

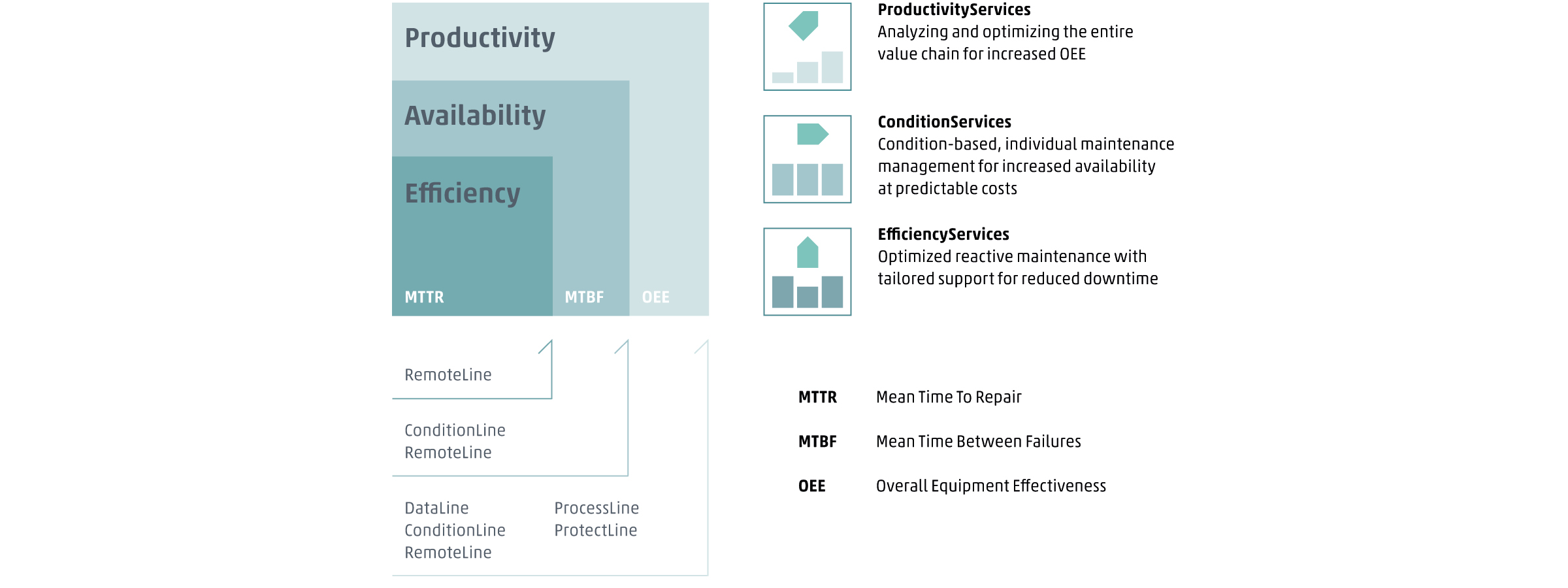

Modular in design, EfficiencyServices, ConditionServices and ProductivityServices can be shaped according to your needs and combined to form the best individual mix. In addition, in order to be most effective, the SmartServices are tailored to the three stages of the machine's lifecycle.

EfficiencyServices

EfficiencyServices enable optimized reactive maintenance with shorter downtimes through guaranteed response times, spare part deliveries and service calls. Using RemoteLine, which provides direct access to the machine data, the experts at CHIRON Group Service can identify faults and, in many instances, resolve them directly, without making a service call.

ConditionServices

ConditionServices focus on ideal maintenance management, with services such as capturing and visualizing condition data, regular reporting, and specific recommended actions. The aim is to achieve an intelligent, long-term maintenance process for a consistently high level of technical availability at fixed, foreseeable costs.

ProductivityServices

The third element for high overall equipment effectiveness are ProductivityServices. Experts scrutinize all areas involved in the manufacturing process, such as hardware and software, automation, process, and set-up times. Any areas of untapped potential are flagged to be exploited with appropriate measures, particularly by integrating additional SmartLine modules.

Contact